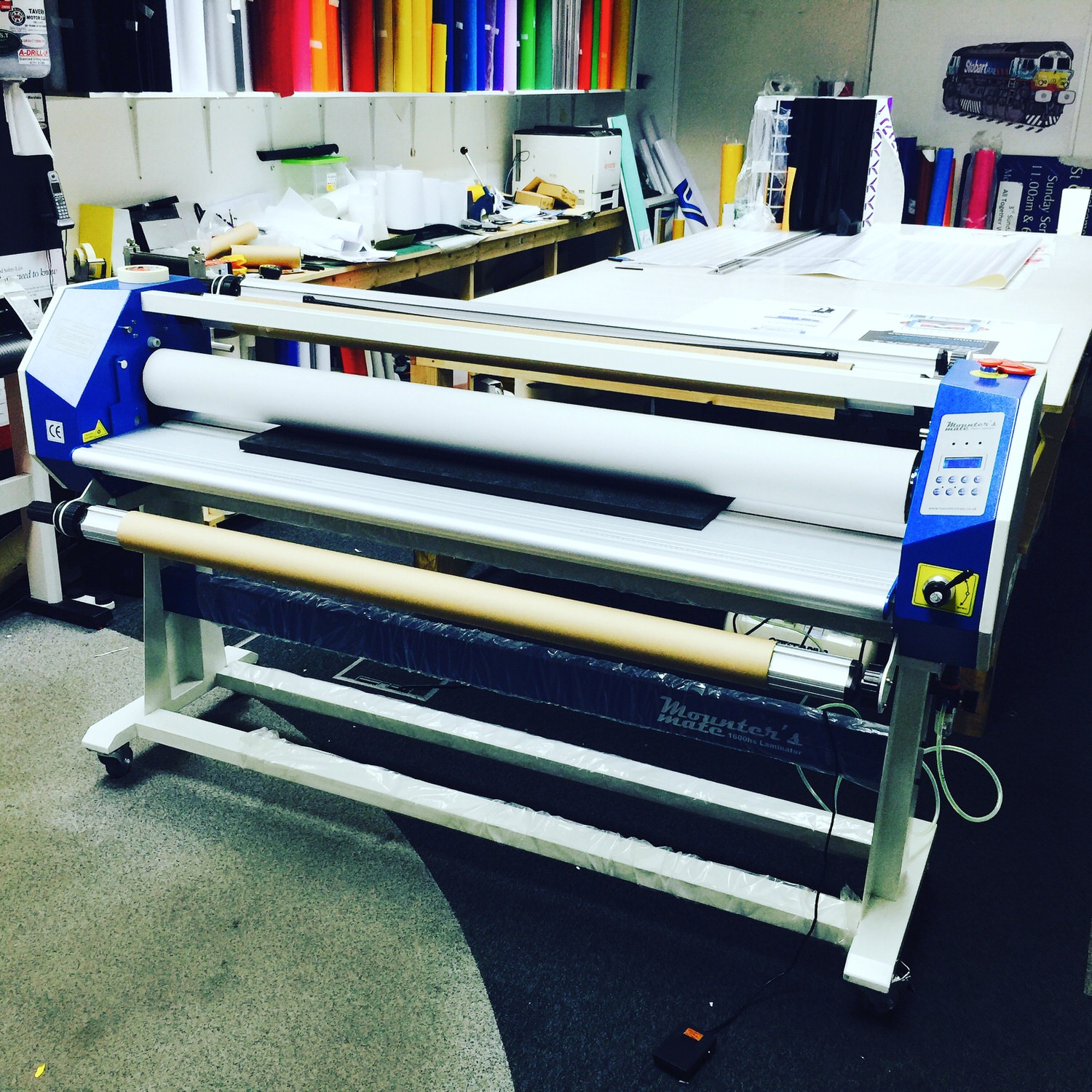

Wide Format LaminatorMounter's Mate 1600hs

For All Your Laminating Needs

The 1600hs wide format laminator allows you to wave goodbye to the days when laminating was a tricky process you would rather avoid until the end of the day. An upright roll to roll machine that is the best in its class, the 1600hs is the easy to implement solution for applying durable laminate to any digital print.

- Quickly and easily mount prints to both rigid and flexible materials

- Apply hot or cold laminates to a range of graphics and print media

- Safely apply hot laminate to all compatible medias

- Accurately apply application tape to your vinyl cut lettering

- Improve the throughput and profitability of your business

1600hs Wide Format Laminator Features

Watch the videos below to see the Mounter's Mate 1600hs in action.

Working With The 1600hs

Learning to operate the 1600hs large format laminator is as quick and easy as all of the Mounter’s Mate products. With field tested components and an intuitive approach to design, with your inclusive on-site training you will be up and running in no time at all.

Perfectly In Sync

A unique pneumatic system applies even pressure to both ends of the roller to ensure a steady feed and even application for years to come.

Uncompromising Safety

With the roller typically applies 3.5bar of pressure for optimal performance, we have placed safety at the centre of everything we do. Emergency stop buttons are located on both the left and right of the machine, whilst a laser eye cuts the power to the motors to prevent trapped fingers. The machine can be foot operated with an ergonomically positioned pedal, allowing you to keep both hands free at the start and end of a job.

A Helping Hand

A take up reel is implemented on the rear of the laminator this runs at the same speed as the laminating rollers. This allows you to easily collect (roll up) your laminated graphics onto a new core and transfer onto the next stage of process.

Quality And Care

A unique tension input system allows the user to apply slight brake against the roll to get the feeding medium perfectly flat and straight as it enters the 1600hs. The feeding tray even comes with a rounded front to smoothly feed the material into the rollers.